In addition, EM 2 has the potential to reduce our waste stockpile because it can be powered with this spent fuel. Even better, these fission products require only about 500 years of storage before decaying to background levels, compared to 10,000 years or longer required for current designs.

No liquid reprocessing is necessary, and no heavy metals are separated. In addition, rather than sending spent fuel out for geologic storage, EM 2 is capable of recycling its used fuel once some of the fission products are removed. The efficient use of fuel by EM 2 means that it generates a fraction of the high-level waste produced by current reactors. Finally, the reactor containment structure is situated entirely below grade, providing added protection from external events. Next, a pair of redundant Direct Reactor Auxiliary Cooling Systems (DRACS) are capable of 100% core heat removal via natural circulation, without any actuation or operator intervention, even under "station blackout" conditions.

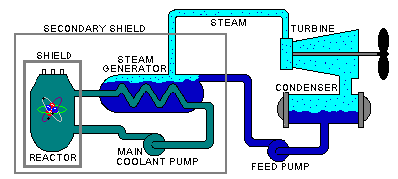

SiGA ® makes the core virtually meltdown-proof and Fukushima-type accidents almost impossible. The fuel, fuel rod cladding, and reactor core and core structures are manufactured from GA-EMS' proprietary SiGA ® silicon-carbide composite, a high-tech ceramic matrix composite that can withstand more than twice the temperatures of the metal components used in current reactors. EM 2 can also use a variety of fuels, including spent fuel from light water reactors.ĮM 2 uses an array of passive safety measures to achieve substantially safer operation than current designs. The "convert and burn" approach means EM 2 utilizes its uranium fuel much more efficiently, generating more power from the same core volume. The simpler direct-drive system also means reduced construction costs, since elements such as the steam generators, the main steam system and the feedwater-condensate system are eliminated. Its higher operating temperature and direct-drive power conversion unit allow EM 2 to achieve a 53% net thermal efficiency, compared to 30% to 35% for current light-water reactors. These approaches allow a four-unit EM 2-based plant to be completed in just 42 months. Because the cost of capital is one of the largest challenges for nuclear plant construction due to long, uncertain construction periods, EM 2 is designed for factory fabrication and modular construction.

COMPONENTS OF NUCLEAR FISSION REACTOR DRIVERS

EM 2 also employs a direct closed-cycle gas turbine power conversion unit for added efficiency.ĮM 2 evolved from a parallel design and cost modelling effort to enable rapid feedback between design decisions and their impact on power cost, thus identifying key cost drivers and targeting them for reduction. The reactor is sited in a below-grade sealed containment and uses passive safety methods for heat removal and reactivity control to protect the integrity of the fuel, reactor vessel and containment. The reactor employs a "convert and burn" core design which converts fertile isotopes to fissile and burns them in situ over a 30-year core life. It is designed as a modular, grid-capable power source with a net unit output of 265 MWe. GA-EMS' Energy Multiplier Module (EM 2) is an advanced small modular reactor (SMR) that addresses four of the most challenging problems facing nuclear energy: economics, safety, waste, and nonproliferation.ĮM 2 is a helium-cooled fast reactor with a core outlet temperature of 850☌. Today, as the nuclear industry faces unprecedented challenges to its future, GA-EMS is helping develop the next generation of advanced reactors. Vrain projects in partnership with the Department of Energy. In this pursuit, GA-EMS draws upon particular expertise and experience with high-temperature, gas-cooled reactors, starting with the Peach Bottom and Fort St. GA-EMS seeks to develop and deploy reactors that advance the state of the art in efficiency, safety, and economics. General Atomics Electromagnetic Systems (GA-EMS) has been at the forefront of innovation in nuclear energy since its founding in 1955.

0 kommentar(er)

0 kommentar(er)